RMU Air Conditioner Cleaning for Climate Cooling

ผู้รับผิดชอบ ให้ข้อมูล : ผศ.วรพันธุ์ สมบัติธีระ

SDG ที่เกี่ยวข้อง

เป้าหมายย่อยความสอดคล้องกับยุทธศาสตร์มหาวิทยาลัย : เสริมสร้างความตระหนักและการปรับตัวต่อการเปลี่ยนแปลงสภาพภูมิอากาศ

แหล่งงบประมาณ : งบประมาณแผ่นดิน

กลุ่มเป้าหมาย : นักศึกษา

Project Implementation Area : มหาวิทยาลัยราชภัฏมหาสารคาม ตำบล Talat อำเภอ Mueang Maha Sarakham จังหวัด Maha Sarakham 44000

Project Duration: July 21, 2025 – August 8, 2025

Objectives :

1. To provide students with knowledge and technical skills in air conditioner maintenance in accordance with Level 1 professional standards for air conditioning technicians.

2. To enable students to apply the acquired knowledge in maintaining air conditioning systems within the university.

3. To contribute to climate change mitigation by promoting efficient energy use and reducing greenhouse gas emissions.

Activities :

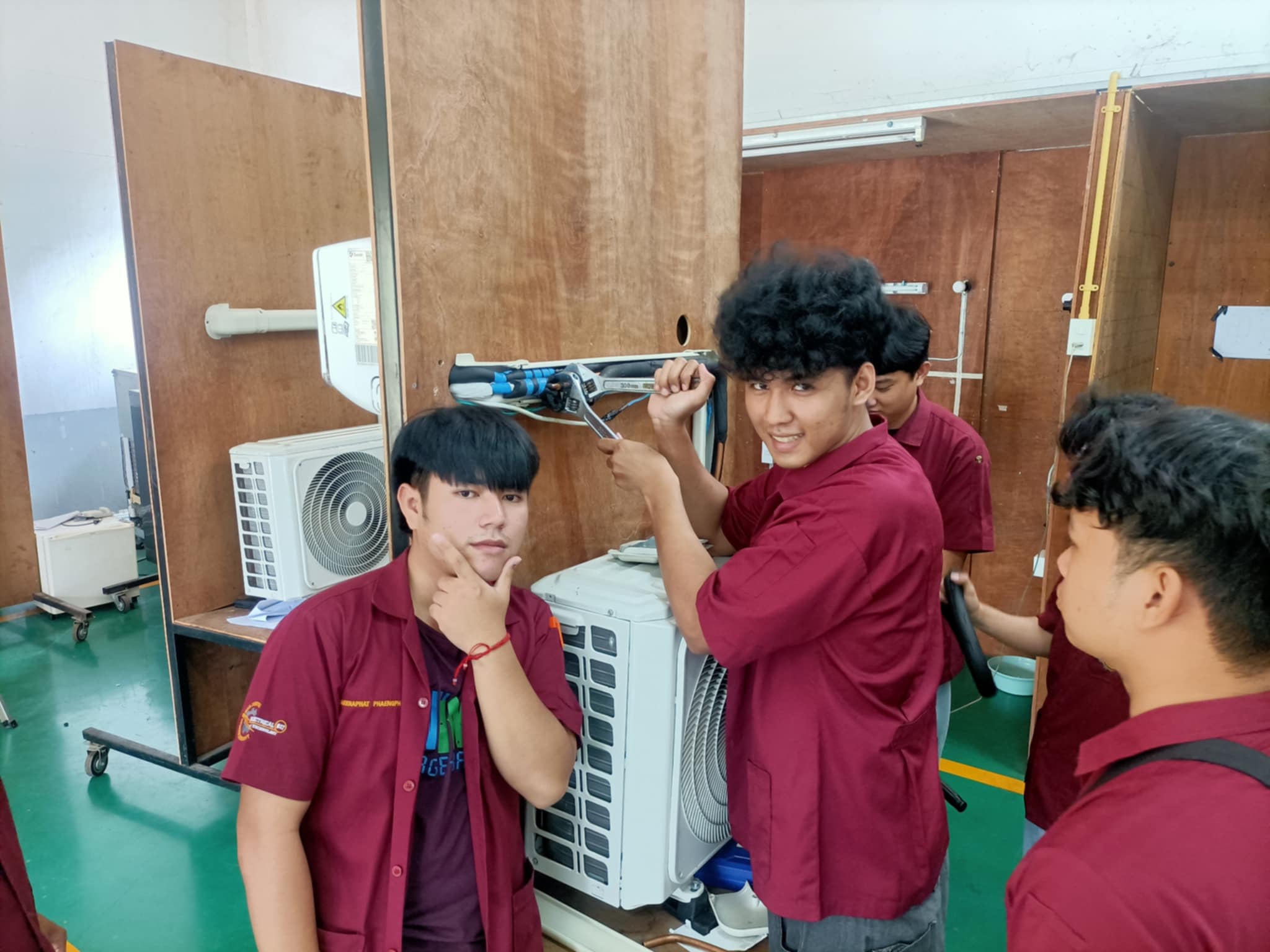

Activity 1: Training in the “Domestic and Small Commercial Air Conditioning Technician, Level 1” course, certified by the Maha Sarakham Skill Development Office. The training was conducted over five days, from 21–25 July 2025.

Activity 2: Practical maintenance of 45 air conditioning units across nine faculties at Rajabhat Maha Sarakham University. The maintenance was carried out over five days, from 4–8 August 2025.

Number of project participants: 23 people

Project Budget: 60,000 Baht

Results :

1. Participants gain professional knowledge and practical skills in air conditioner maintenance that can be applied to future employment.

2. Students engage in real-world practice, developing confidence and expertise in air conditioning maintenance.

3. Participants develop environmental awareness and an understanding of energy conservation, leading to more efficient air conditioner usage.

Results society :

1. Produced skilled personnel in air conditioner maintenance, contributing to the local labor market and providing technical services to the community.

2. Reduced energy consumption and greenhouse gas emissions, thereby mitigating local climate impacts.

3. Served as a model for integrating teaching, learning, and community engagement, with potential for replication in other units or communities.

Participation :

- Student Participation: Engineering students participated in the official “Domestic and Small Commercial Air Conditioning Technician, Level 1” training program by the Maha Sarakham Skill Development Office, engaging in both theoretical and practical components.

After the training, students applied their knowledge by cleaning and maintaining air conditioning units within university buildings. Their responsibilities included site surveys, operational planning, recording energy consumption before and after cleaning, and reporting post-maintenance performance results.

- Faculty and Staff Participation: Faculty members acted as advisors and supervisors throughout project implementation. They also prepared tools and equipment and coordinated with the Maha Sarakham Skill Development Office.

Project continuity :

1. Project Expansion:

Extend maintenance activities to cover additional university departments and offer services to external community organizations, creating income and establishing an academic service center under the Faculty of Engineering.

2. Short-Course Development:

Develop a short-term training course titled “Air Conditioner Maintenance for Climate Change Mitigation” for students and the general public to promote knowledge transfer in energy efficiency and environmental management. 3. Integration with Teaching and Research:

Use data collected from maintenance activities (e.g., efficiency measurements, energy use before and after maintenance) to support teaching and research on energy conservation.

4. Establishment of an Engineering Service Center:

Lay the groundwork for a “Clean Energy and Air Conditioner Maintenance Service Center” under the Faculty of Engineering to provide commercial services in accordance with Ministry of Finance regulations and promote long-term faculty sustainability.

Problems obstacles :

1.Implementation Constraints:

1.1 Limited training and maintenance periods required accelerated scheduling for some activities.

1.2 Overlapping classroom use sometimes conflicted with maintenance schedules, necessitating rescheduling or after-hours work.

2. Equipment and Budget Limitations:

2.1 Budget constraints limited the procurement of high-quality tools and equipment for certain air conditioner types.

2.2 Insufficient measurement instruments (e.g., sound meters, energy efficiency analyzers) prevented simultaneous data collection at all sites.

3. Participant Issues:

3.1 Some students lacked foundational technical knowledge, requiring additional instruction.

3.2 Inconsistent participation due to overlapping academic or extracurricular commitments affected training continuity.

4. On-Site Conditions:

4.1 Some air conditioners were too old or damaged for standard maintenance, limiting performance improvement.

4.2 Variations in dust, humidity, and building use produced inconsistent maintenance outcomes across locations.

Improvement :

1. Schedule project activities at least one semester in advance and coordinate with the Facilities Division to reserve maintenance areas.

2. Divide students into smaller teams to alternate fieldwork and optimize time management.

3. Introduce online training components to reduce theoretical instruction time.

4. Borrow measuring instruments (e.g., sound and energy meters) from other academic departments.

5. Develop concise manuals and instructional videos for students' self-learning.

6. Inspect air conditioners prior to maintenance and exclude units beyond repair.

7. Submit reports to university administrators recommending replacement or repair of severely damaged units.

8. Establish an annual preventive maintenance schedule to ensure consistent upkeep.

Suggestions :

1. Extend training and fieldwork durations to provide more comprehensive hands-on experience.

2. Acquire additional precision instruments such as energy and air quality meters to improve data accuracy.

3. Prioritize maintenance for units that can still be improved according to performance standards.

4. Develop operational manuals and training videos to support self-directed learning for students with limited technical background.

5. Request an increased budget allocation for the following year to accommodate a larger number of participants and air conditioning units.